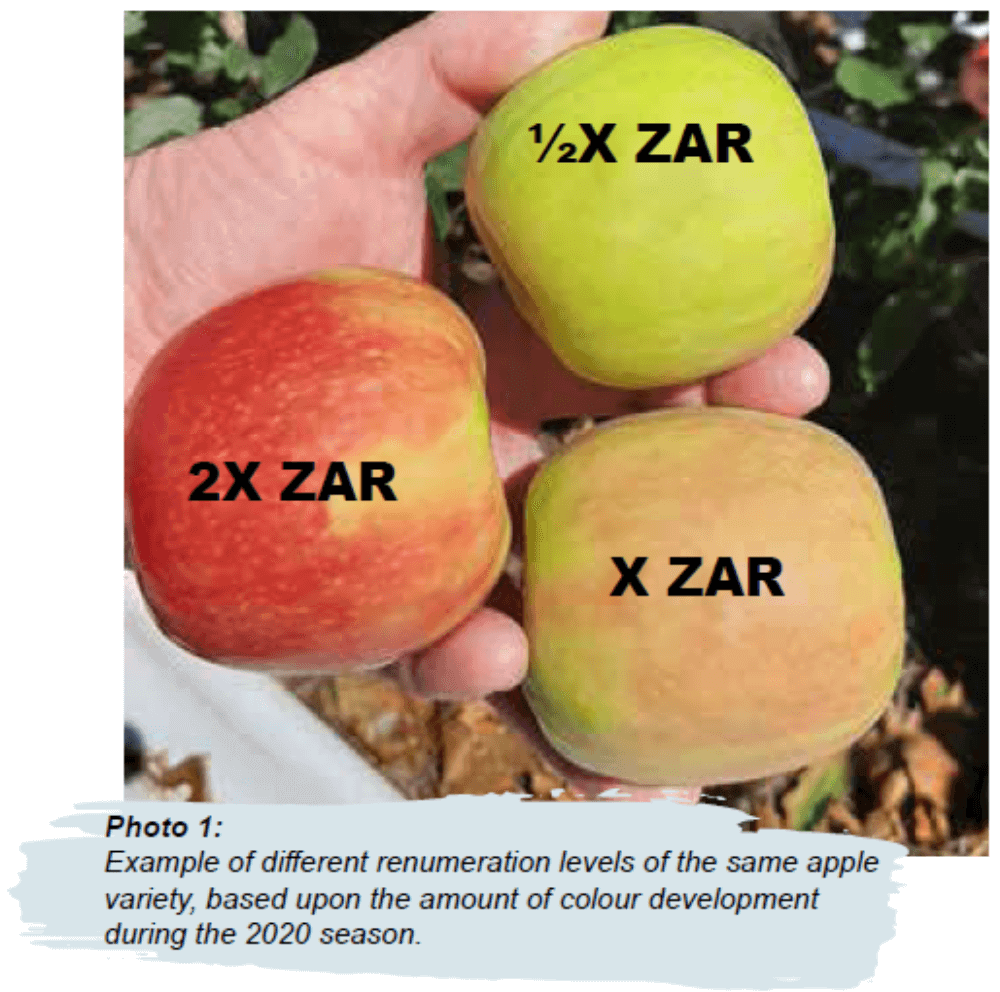

Farming with apples is one thing, but farming with apple varieties of colour increases the challenge of producing a higher percentage of superior class apples (with the accompanying higher remuneration), primarily based on colour development. It is not uncommon for fruit from the same variety to differ 2 to 3 times in price, based upon increased colour development.

Example of different remuneration levels of the same apple variety, based upon the amount of colour development during the 2020 season.

During the 2019/ 2020 apple season in the Western Cape Province of South Africa commercial investigations were conducted with ColourUp to determine whether the product could contribute towards improved colour development of various apple varieties of colour.

ColourUp

ColourUp is a proprietary translaminar liquid Calcium Complex which works with the plant’s natural ripening and colouring stages on various fruit and vegetable types. The product is manufactured by Miller® Chemical & Fertilizer, LLC in Hanover, Pennsylvania,17331, United States of America. ColourUp is imported to South Africa by Hygrotech South Africa (Pty) Ltd. The name ColourUp is used only in South Africa and is registered as a Group 2 Fertilizer (Reg. No. B3386 of Act 36 of 1947). Internationally the product is known, marketed, and sold as Calexin® in countries such as the USA, Peru, Chile, Costa Rica and Australia, and CalXpress in New Zealand. ColourUp is applied as a foliar spray and is totally systemic. Being part of the Miller® patented Nutrient Express® technology products, ColourUp focuses mainly on plant energy production and contains no hormonal substances. During periods of rapid growth, fruit development and ripening, plants require energy for proper physiological development and high levels of calcium for fruit quality. Physiological and environmental crop stress slows down plant metabolism and the movement of calcium within plant tissue. Consequently, plants may suffer, crop development may weaken, and fruit may lack necessary nutrients (including calcium) required for optimum harvest quality. International documented benefits from ColourUp applications include calcium mobilization to fruit and supporting natural colour development. Known commercial crop uses of ColourUp in South Africa include table grapes, mangoes, and citrus.

Trials

Locations and apple varieties

- Trials were conducted in 5 different areas (Koue Bokkeveld, Elgin, Helderstroom, Greyton and Riviersonderend). As many as possible bicolor apple varieties were evaluated. These were Gala, Pink Lady, Sundowner, Rosy Glo and Fuji.

ColourUp rate and application timings

- ColourUp was applied 3 times at 10 – 14-day intervals at 2 L/ ha by means of tractor mounted commercial spray equipment. Applications commenced when at least 80% of the apples in the orchard had developed or had started developing colour.

Commercial harvesting practices

The general commercial harvesting practices in the Western Cape may be as follow:

- First pick: Quick process during which fruit that are mature (adequate colour development) ahead of the bulk fruit load are harvested and placed in cool storage. This fruit are packed after two weeks in cool storage.

- Second pick: This is the main harvesting stage. Harvested apples are kept “fresh” in controlled-atmosphere storage often for months. During these months of storage, the objective is to sort, pack and deliver these apples during optimal marketing (economical) opportunities.

- Third pick: This process is similar to the first pick, but in this case, it is late maturing fruit or fruit from a later fruit set.

These practices do however vary among growers and apple varieties. While some varieties go through all three harvesting stages, other varieties are only harvested once (with the aim of having as many fully coloured fruit as possible at that time). These various harvesting procedures had an obvious effect on the assessments of these commercial trials.

Assessments

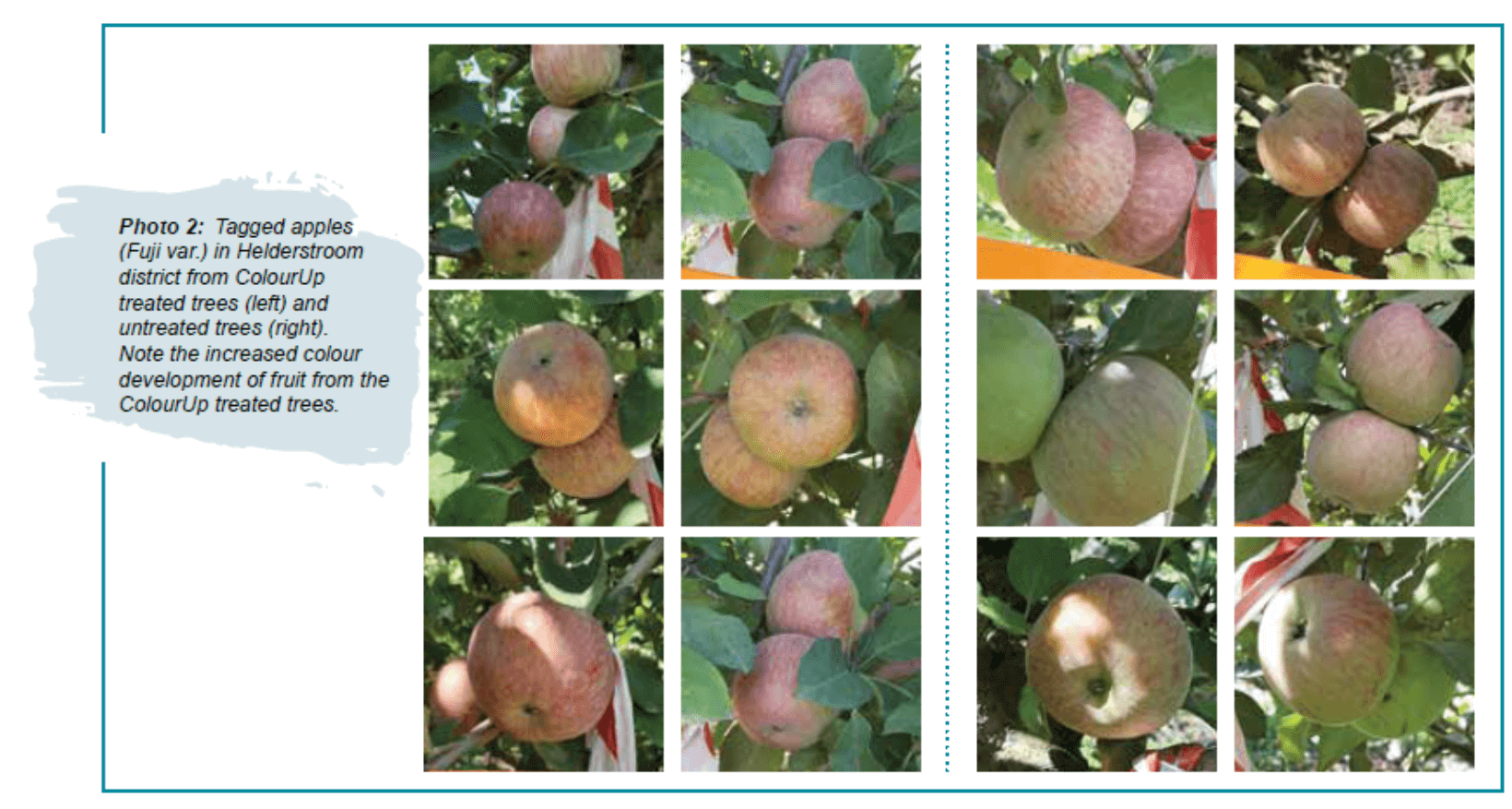

Randomly tagged apples from randomly chosen trees within ColourUp treated and untreated orchards were frequently monitored for colour development during the trial period. The tagged fruit were sampled as close to commercial harvest as possible. This depended on whether the grower harvested over three picks or only once. Fruit sampled from orchards harvested three times often showed less colour development compared to fruit harvested once only, as the objective of a single harvest is to maximize the presence of fully coloured fruit at picking. In contrast, fruit from trees destined for multiple picks had to be sampled earlier to avoid losing tagged fruit, which affected colour development and final data.

Results

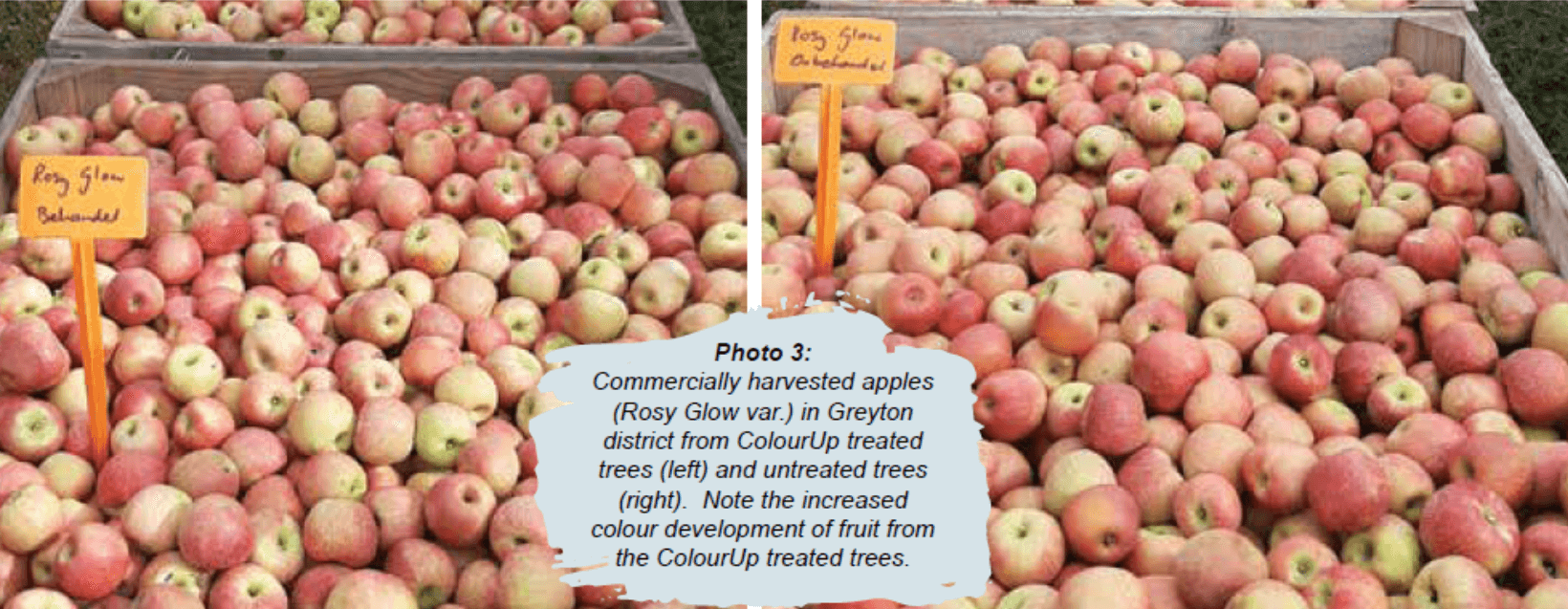

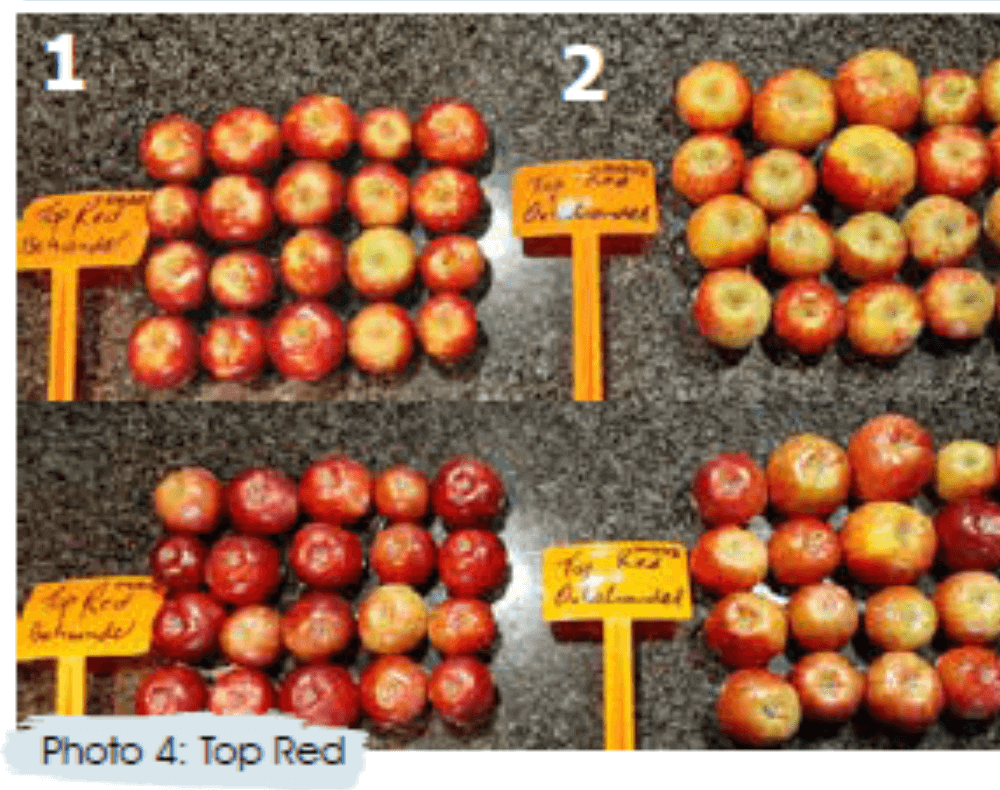

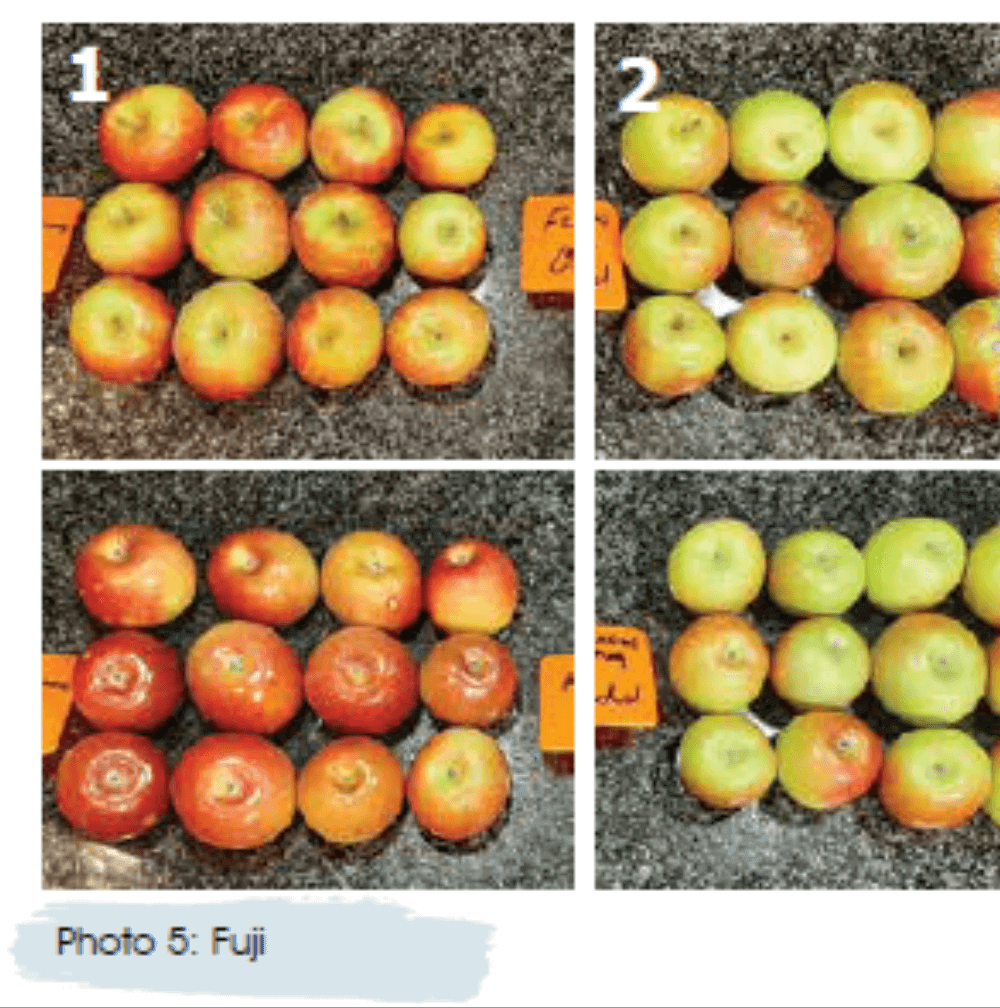

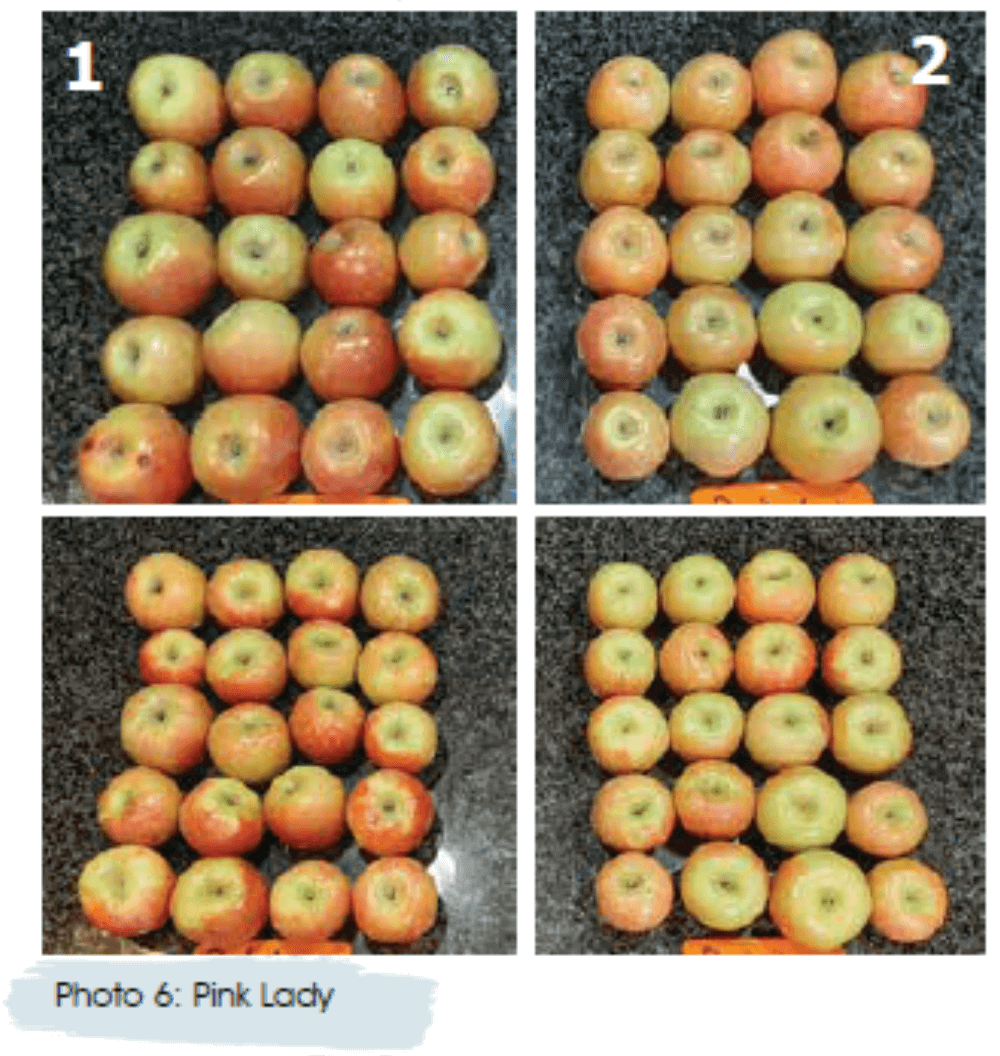

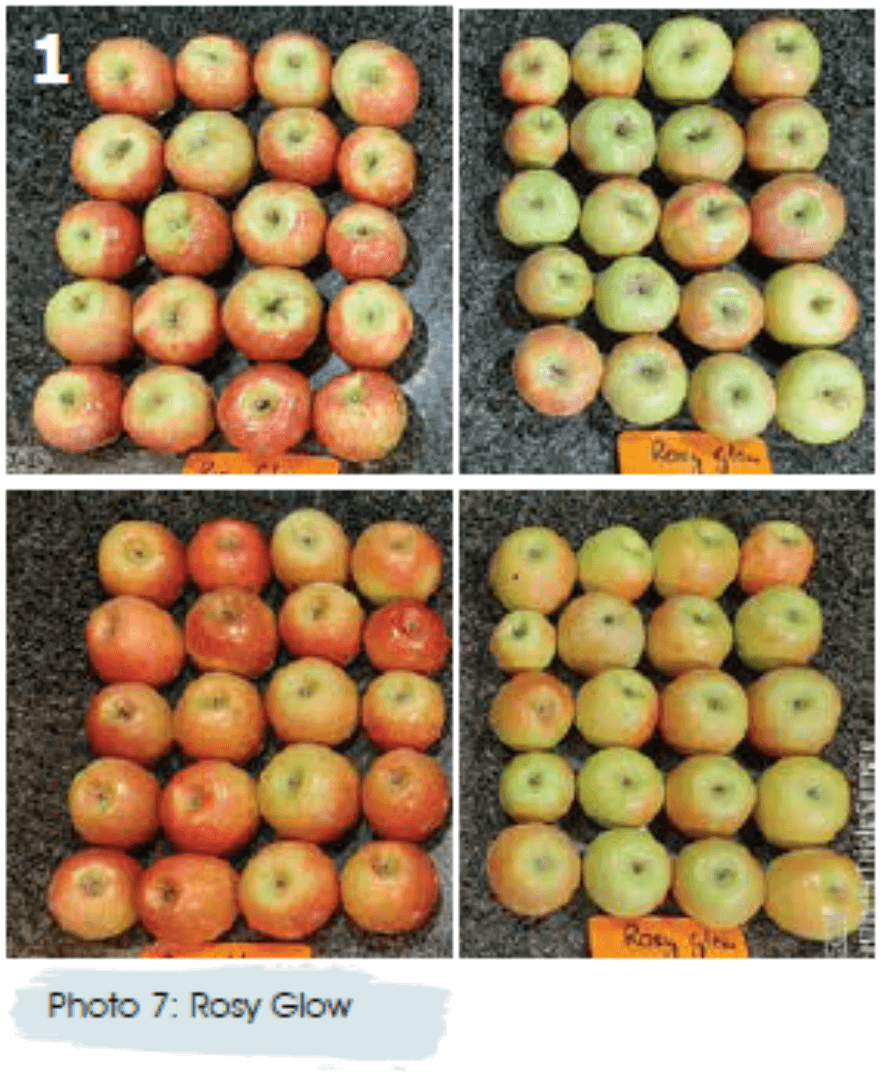

In most of the trial locations the increase in fruit colour development from ColourUp treated trees compared to untreated trees were visible in the orchard (example Photo 2) and also in the commercial picking bins (Photo 3). The extent of the ColourUp treatments are however better visually illustrated by comparing the sampled fruit next to each other (Pictures 4 to 8).

Should you require more information regarding the use of ColourUp on apples, contact your nearest Hygrotech branch or Herman Walters (hermanw@hygrotech.co.za).

1 Treated / 2 Untreated

Photos 4 – 8: Sampled apples of various varieties (as indicated) from ColourUp treated (left) and untreated trees (right) from various trial locations.

(Written by Herman Walters – Hygrotech Technical Manager: Southern Region)